Brake Disc CNC Grinder

Delivery Date:

Description:

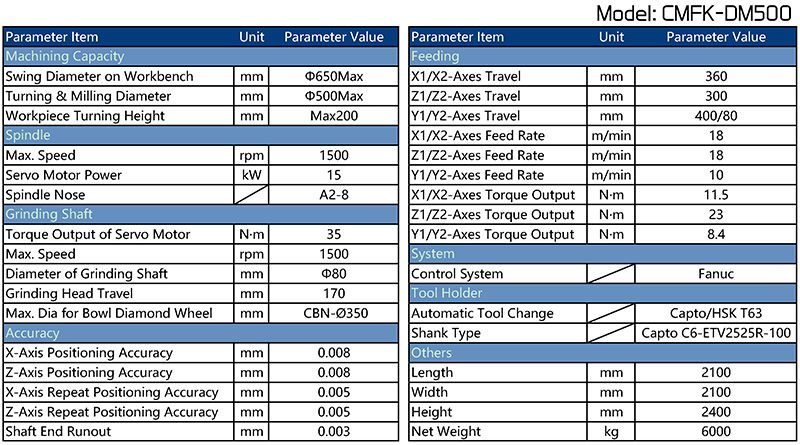

Model:

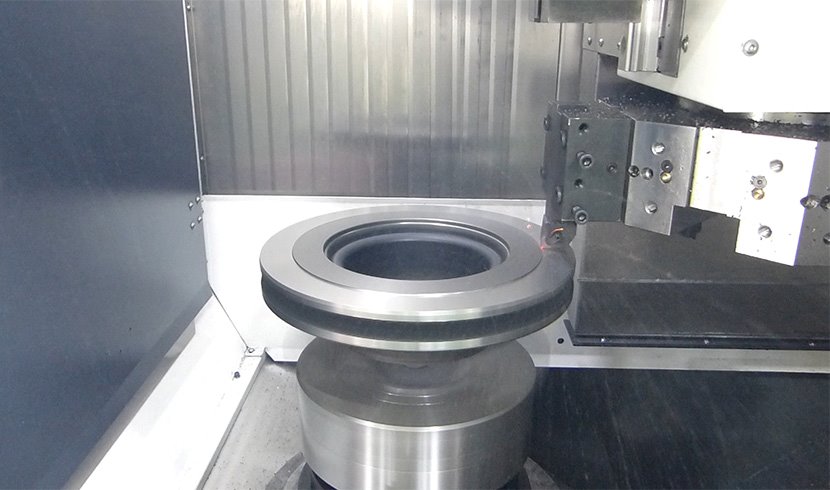

The CMFK-DM500 Double-face grinding machine for brake discs is specifically developed for the integrated turning and grinding of brake discs. The semi-finished brake disc blank can be clamped once to complete the fine turning process of the double brake surfaces. At the same time, the double-face grinding process of the brake disc is carried out to avoid errors caused by repeated loading and unloading, which significantly reduces labor and enhances production efficiency.

The equipment features a portal column design, vertical workpiece spindle, double tool holder, and vertical grinding spindle, which can be integrated with preceding and subsequent processes. It can be automated for loading and unloading by a robotic unit, or done manually. It is an optimal choice for the automotive brake disc processing industry, particularly for the batch production of small to medium-sized brake disc hub parts with diameters ranging from 100 to 450mm.

|

|

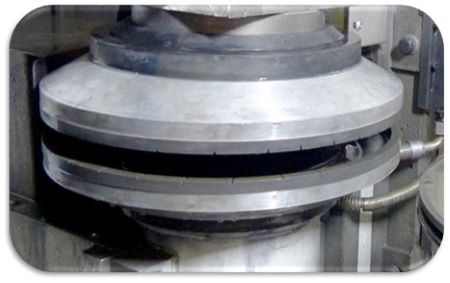

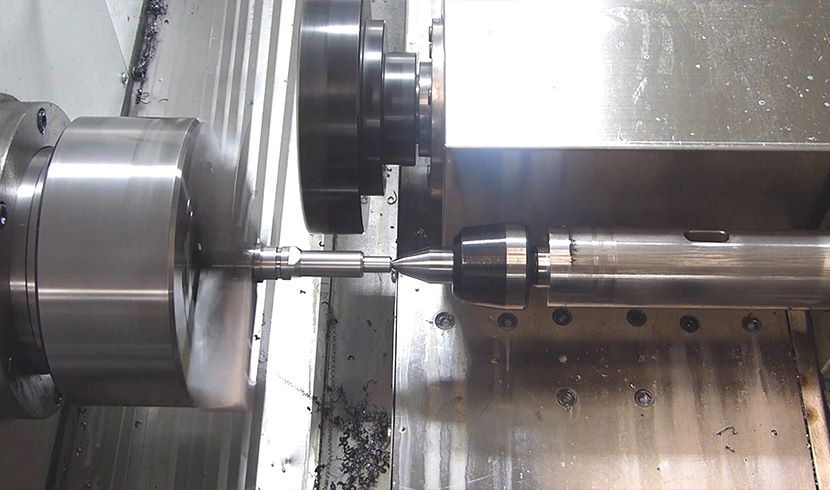

SPINDLE UNIT AND CHUCK ► Taiwan brand spindle unit 2000rpm, servo spinde motor, using special replaceable tension and compression device, instead of ordinary chucks. |

|

|

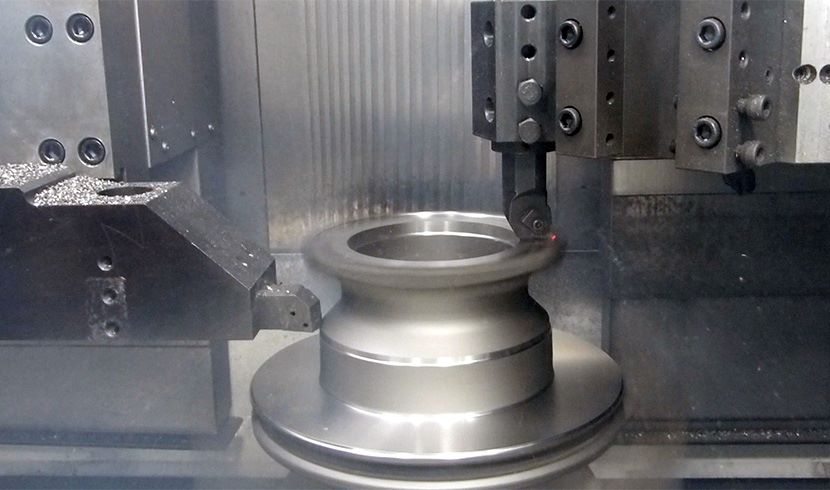

GRINDING ASSEMBLY ► Controlled by the servo motor adopts the double-sided grinding mode for the brake disc, using the bowl diamond grinding wheel, has the torque sensing function. |

|

|

|

|

TURNING STATION & CLAMPING DEVICE ► Equipped with automatic pressing plate tension assembly, workpiece tooling position detector. ► Servo motor controls ST tool holder. |

|

The CMFK-DM500 Brake Disc Double-face Grinding Machine features:

1. The lathe bed of the CMFK series brake disc grinding machine is made of a thermally symmetrical box-type reinforced cast iron structure made from HT300 gray cast iron, which can minimize thermal deformation and provide strong support for heavy cutting;

2. The workpiece spindle unit features a high-stiffness bearing support structure, offering excellent rigidity and high rotational accuracy. The entire spindle system is characterized by long lifespan, low temperature rise, good accuracy retention, and ease of maintenance;

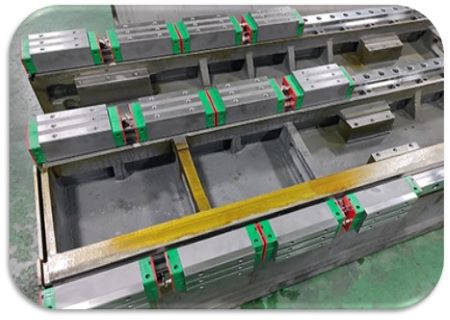

3. The equipment features a double-column double-feed structure, each column is equipped with X, Z, and Y feed axes, utilizing long heavy-duty roller sliders to effectively ensure the rigidity and stability of equipment operation;

|

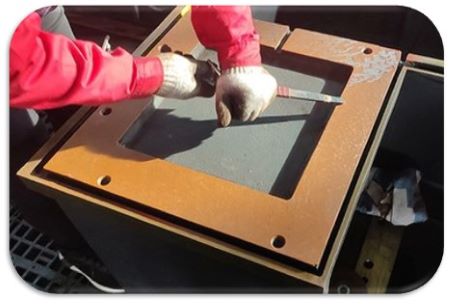

MACHINE BASE ► The lathe body is made of HT300 gray cast iron thermal symmetrical box reinforced cast iron structure, which can minimize thermal deformation and provide strong support for heavy cutting. ► The bed base and main contact surfaces are processed by hand scraping. |

|

|

|

|

TAIWAN LINEAR RAIL&BALL SCREW ► Double column portal type structure, symmetric. ► Adopt high-quality Taiwan linear guide rails and ball screws with large bearing capacity to ensure the positioning accuracy and repeatability of isotropic movement. |

|

|

SYSTEM CNC CONTROL ► Standard: GSK, KND ► Optional: Siemens, Fanuc, Syntec, and others |

|

|

4. The two Z-axes feature a vertical column structure, with the numerical control system operating independently through a dual-channel mode;

5. The grinding head assembly adopts a dual-surface grinding mode for the brake disc, featuring a torque self-sensing function, which can automatically adjust the feed speed based on the remaining material on the workpiece to ensure the efficiency and stability of the workpiece processing;

6. The internal structure features a vertical and steep sloped chip removal design, lined entirely with stainless steel chip guide plates to reduce thermal deformation caused by localized heating from chip accumulation, and to ensure the continuous processing accuracy of the brake disc grinding machine.

CMFK-DM500 CNC vertical grinding machine can be combined with automatic production line for product processing, automatic clamping tool, double brake surface finishing and disk surface grinding.

The device is a double-column double-feed structure, and the numerical control system operates independently through the dual-channel mode. Each column is equipped with X, Z, Y three feed shaft, grinding head assembly adopts grinding mode for grinding, with torque sensing function, can automatically adjust the feed speed of grinding head according to the size of machining workpiece allowance, to ensure the timing and accuracy of workpiece processing.