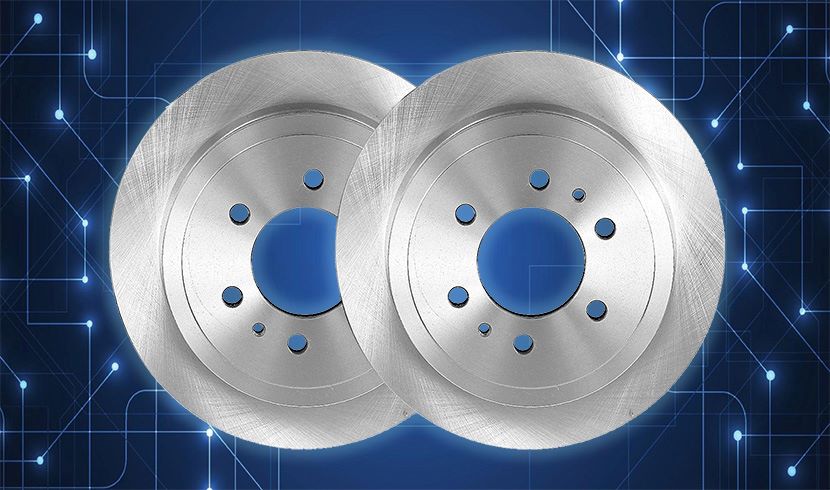

The CMFK-LS500 CNC dual-feed vertical turning and grinding machine, developed by our company, features dual turrets, a dual-channel control system, and a high-power design. These tool sets are capable of simultaneously performing operations such as turning, internal circle grinding, end face finishing, and inverted face processing. This machine is extensively applied in the machining of various disc and shell components, including automotive brake discs, hubs, brake hubs, flywheels, clutch pressure plates, bearing rings, gears, and other parts requiring rough and finish machining as well as grinding processes.

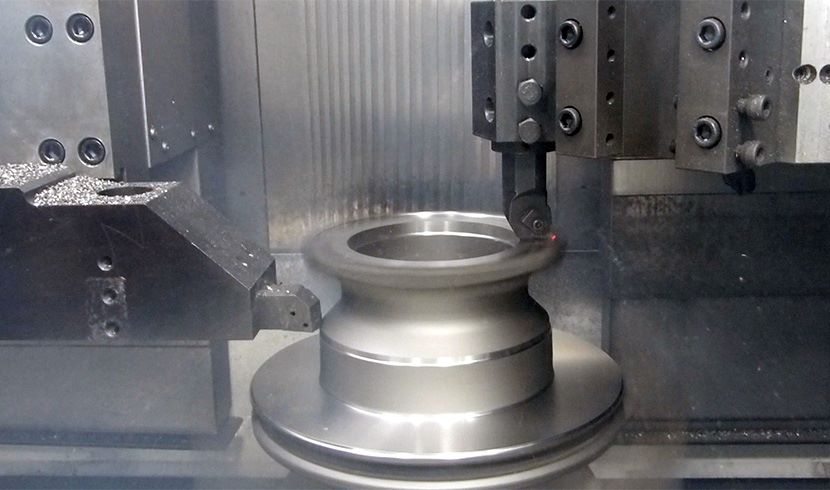

High Processing Efficiency: The dual-feed configuration enables concurrent turning and grinding operations. Additionally, the machine supports high-speed turning, significantly enhancing processing efficiency—up to 4 to 6 times that of conventional lathes—while also improving the surface quality of the workpieces.

|

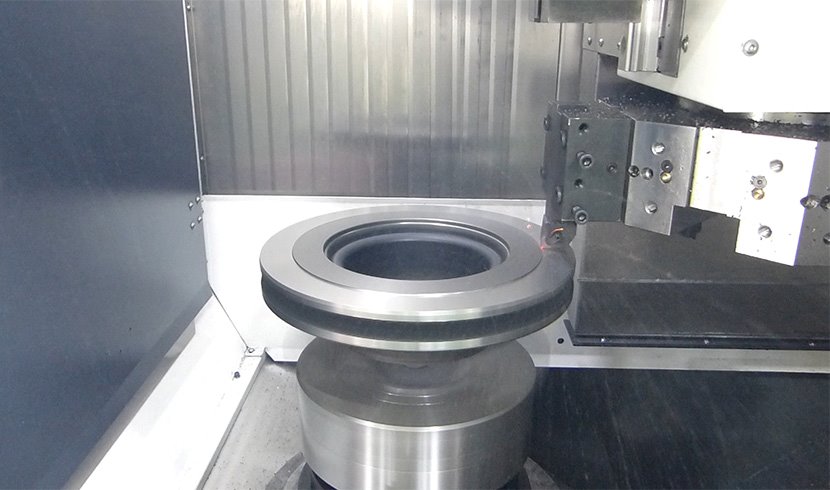

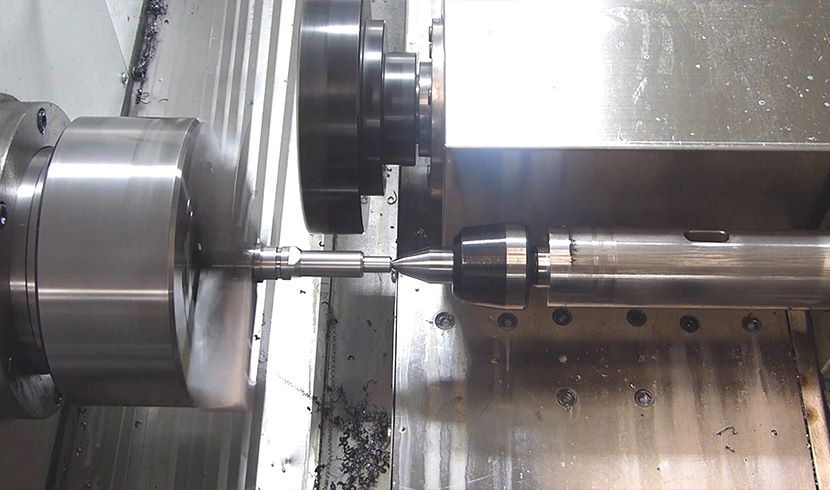

| SPINDLE UNIT AND CHUCK ► Taiwan brand spindle unit 2000rpm. ► The lathe spindle structure is a high-speed, high-precision, high-rigidity shell-type spindle unit. ► Standard Chuck: 500 mm 3-jaw hydraulic chuck |

|

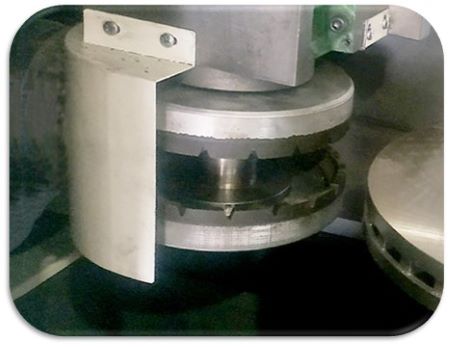

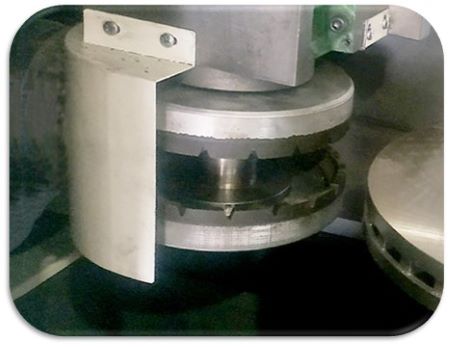

GRINDING SHAFT ► The bowl-shaped CBN grind wheel with a diameter of 300mm is used for grinding the double brake surfaces. |

|

|

|

|

| 8-STATION HYDRAULIC TURRET ► Equipped with an eight-station turret and a double-sided finishing Y-axis, which can realize a clamping and complete multiple processing processes of rough and fine integration. |

|

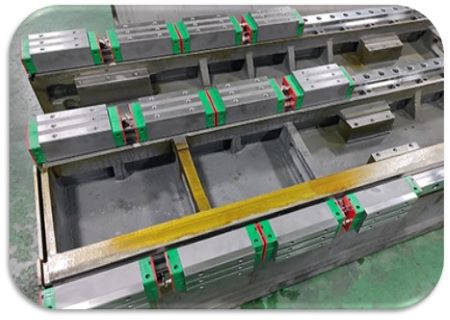

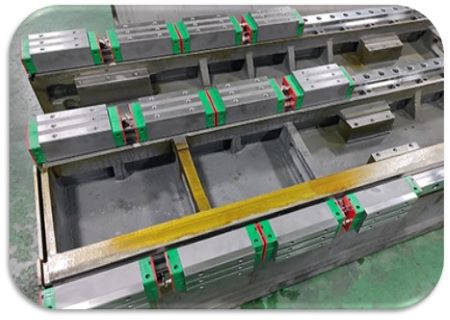

TAIWAN LINEAR RAIL&BALL SCREW ► Double column portal type structure, symmetric. ► Adopt high-quality Taiwan linear guide rails and ball screws with large bearing capacity to ensure the positioning accuracy and repeatability of isotropic movement. |

|

|

|

|

|

SYSTEM CNC CONTROL ► Standard: GSK, KND ► Optional: Siemens, Fanuc, Syntec, and others |

As a specialist in the vertical machining of brake discs, Hengga collaborates closely with customers to develop customized, turnkey manufacturing solutions. We are dedicated to delivering fully automated production systems for brake disc processing.

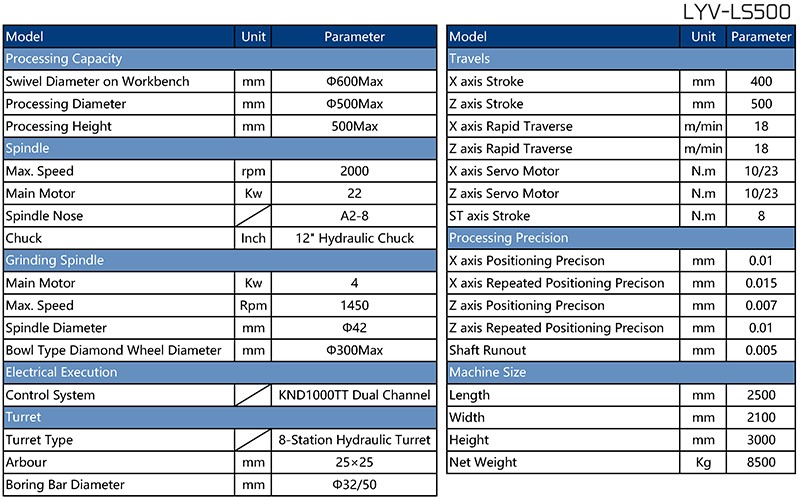

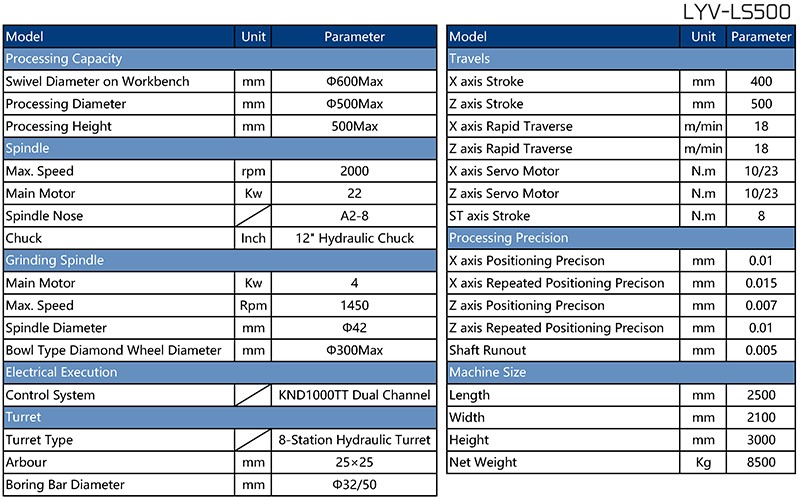

LYV-LS500 Brake Disc CNC Grinder weight reaching 8.5 tons, the rigidity is stronger; the rotating diameter of the workpiece is 500mm, and the range of products that can be processed is wider. This machine can be applied in high precision and automatic mass production of brake discs/drums.

To view the LYV-LS500 brake disc CNC grinder processing video case, please CLICK HERE.

To view the LYV-LS500 brake disc CNC grinder processing video case, please CLICK HERE.

To view the LYV-LS500 brake disc CNC grinder processing video case, please

To view the LYV-LS500 brake disc CNC grinder processing video case, please