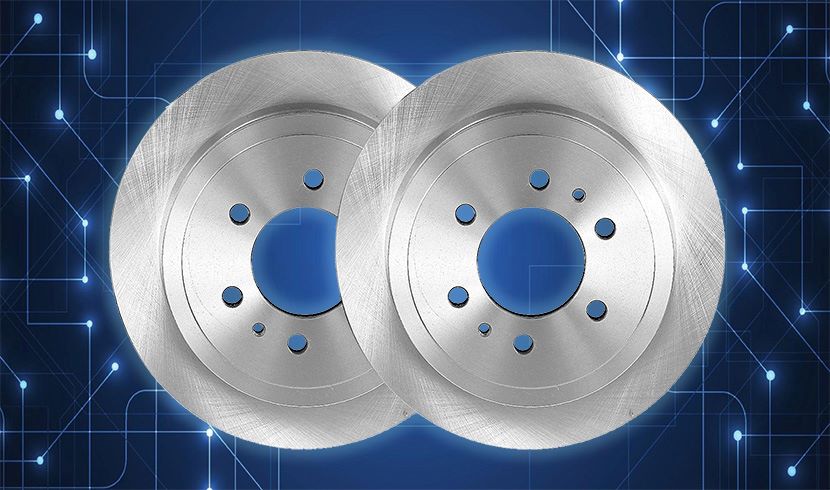

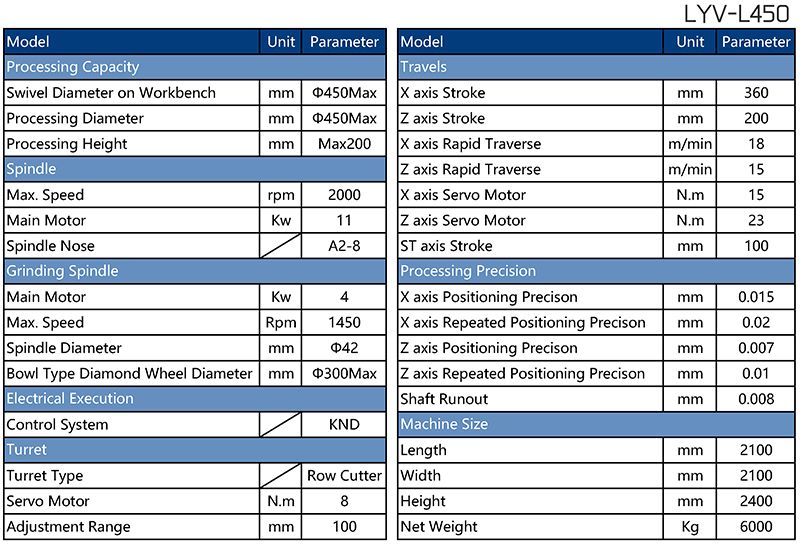

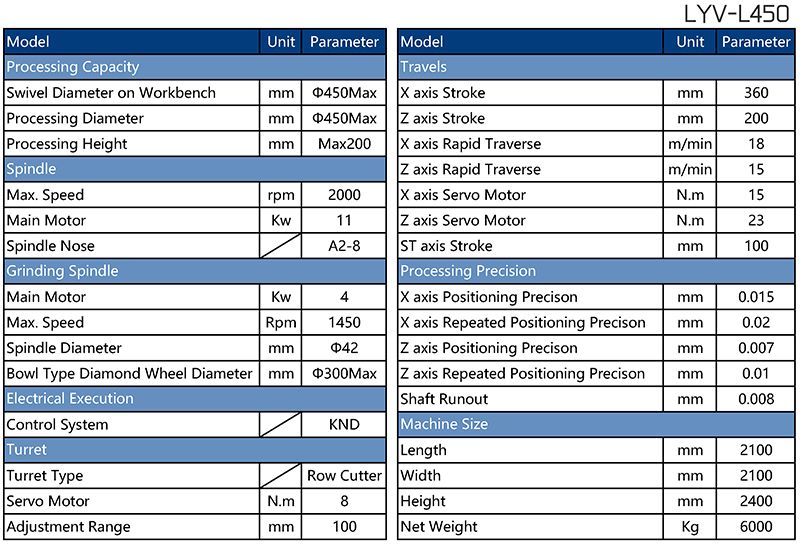

LYV-L450 Brake Disc CNC Grinder can complete the two processes of finish turning and grinding of the brake surface of the brake disc and double car in one clamping, which solves the accumulated errors in the secondary clamping and improves the processing efficiency.

Main Features

1, The LYV-L450 is a vertical turning and grinding machine designed to meet the demands of high-volume, rapid-cycle brake disc production. It is equipped with high-speed steel and carbide cutting tools for machining internal and external cylinders, end faces, grooving, chamfering, and other operations. The machine also features a CBN grinding wheel for finishing the end surfaces of discs, rings, complex disc geometries, and short-shaft metal components.

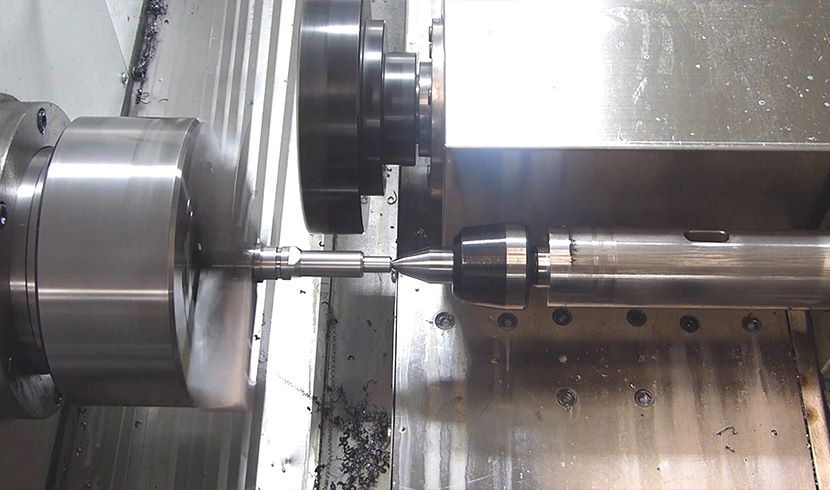

2, Heavy-duty linear guideways, integral base castings, and hardened wheel head guides ensure a robust and rigid machine structure, minimizing vibration, movement, and displacement.

3, By integrating turning and grinding operations into a single machine, the LYV-L450 ensures fast processing and reduces the unit cost of brake disc production.

4, With the LYV-L450 series of compound grinding lathes, Hengga provides production solutions that seamlessly combine quality, productivity, and process reliability.

5, Hengga's machines are engineered to meet the high-volume and fast-cycle demands of brake disc manufacturing.

6, As a specialist in the vertical machining of brake discs, Hengga collaborates closely with customers to develop customized, turnkey manufacturing solutions. We are dedicated to delivering fully automated production systems for brake disc processing.

|

|

|

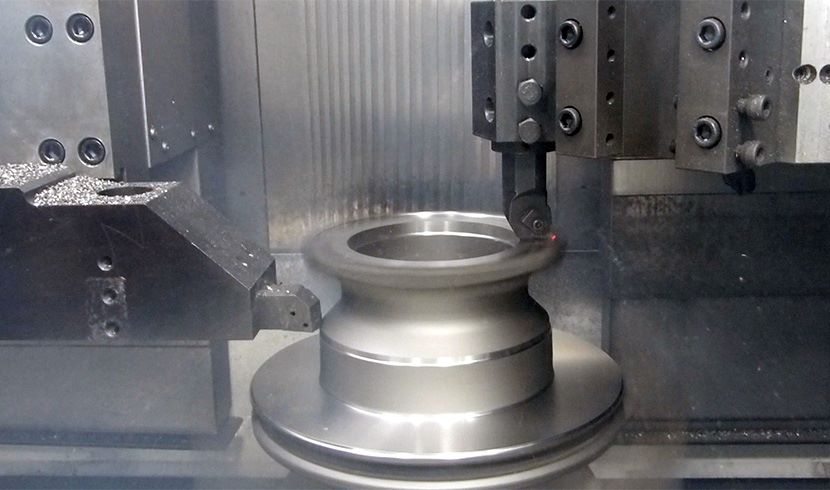

SPINDLE UNIT AND CHUCK

► Taiwan brand spindle unit 2000rpm.

► The lathe spindle structure is a high-speed, high-precision, high-rigidity shell-type spindle unit.

► Standard Chuck: Special replaceable clamping device.

|

|

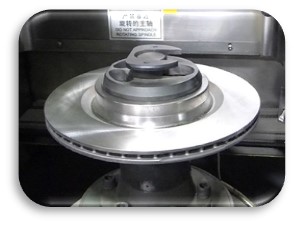

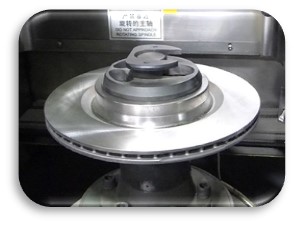

GRINDING SHAFT

► The bowl-shaped CBN grind wheel with a diameter of 300mm is used for grinding the double brake surfaces.

|

|

|

|

|

|

|

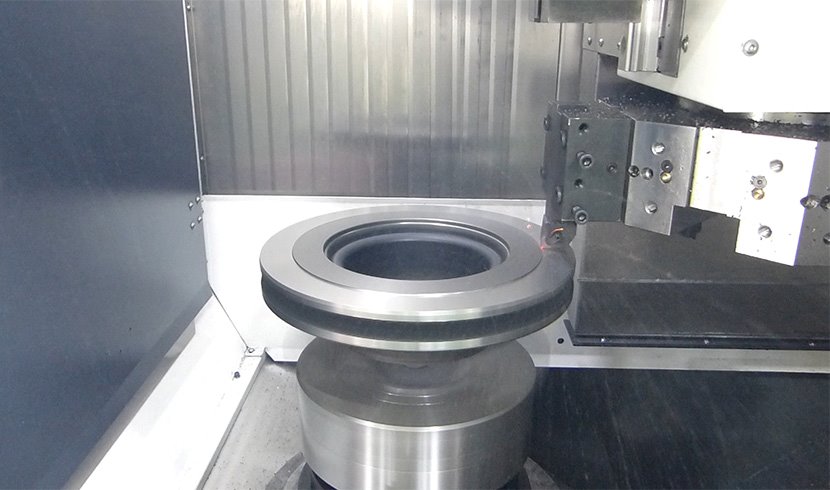

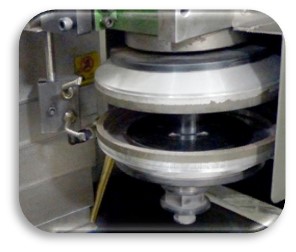

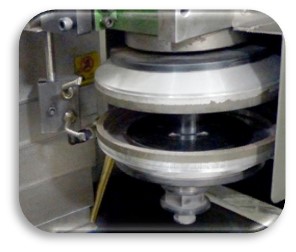

TAIWAN LINEAR RAIL&BALL SCREW

► Double column portal type structure, symmetric.

► Adopt high-quality Taiwan linear guide rails and ball screws with large bearing capacity to ensure the positioning accuracy and repeatability of isotropic movement.

|

|

SYSTEM CNC CONTROL

► Standard: GSK, KND

► Optional: Siemens, Fanuc, Syntec, and others

|

|

|

|

|

|

|

LUBRICATION

► Using a reliable centralized automatic lubrication device.

► Regular, quantitative automatic lubrication of the lubrication points of the machine tool, lubrication time can be adjusted according to the working conditions

|

To view the LYV-L450 brake disc CNC grinder processing video case, please CLICK HERE.

To view the LYV-L450 brake disc CNC grinder processing video case, please CLICK HERE.

To view the LYV-L450 brake disc CNC grinder processing video case, please

To view the LYV-L450 brake disc CNC grinder processing video case, please