For the assembly line design of the brake disc automatic production line, we conducted a more detailed inspection of the market, aiming at the needs of the product market and the production needs of current manufacturers, including various forms of existing production lines, combined with domestic and foreign with some advanced technologies, we have made the following equipment assembly line production plan for the mechanical processing production line:

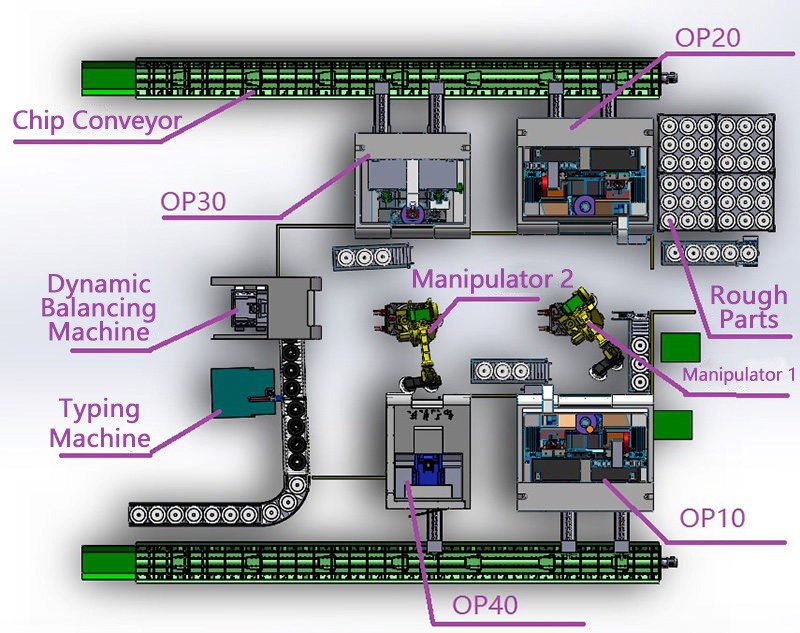

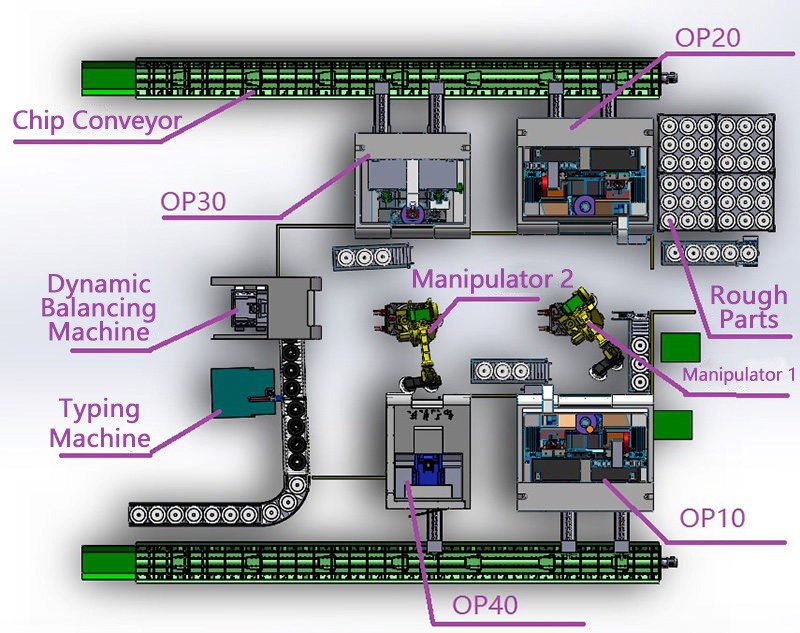

The composition of a single manipulator production line (as shown in the figure below): two double-station rough and fine integrated vertical turning machine tools (LYV-SD500) OP10 and OP20, one drilling and tapping machining center (LV850) OP30, one vertical turning and grinding integrated machine tool (LYV-L450) OP40, a dynamic balancer, a pneumatic or laser typing machine string combination, including two 150KG six-axis mainpulators and roller line for handling, loading and unloading and transporting workpieces.

1. First, place the material frame with the Brake disc blank parts in the designated position according to the above sequence, and the manipulator 1 automatically grabs the workpiece and clamps it on the double-column brake disc CNC vertical lathe OP10 for processing;

2. After the brake disc blank is clamped on the OP10, the workpiece in-position signal is detected, the chuck performs automatic clamping of the workpiece, and the chuck clamps one end of the air duct of the workpiece to turn the other end;

3. OP10 performs the rough and fine processing of the brake disc surface, and after the processing is completed, the manipulator grabs and unloads the material; and puts another workpiece;

4. After the manipulator is unloaded by the OP10 equipment, it is turned over, and then sent to the OP20 for clamping, and the rough and fine processing of the brake disc surface is carried out. After the processing is completed, the manipulator grabs the material and puts another workpiece for processing. The processed workpiece enters the next process;

5. After the double surfaces of the brake disc is processed, it is grabbed by the manipulator and sent to the OP30 drilling and tapping machining center for indexing and drilling;

6. After the machining of the drilling and tapping center is completed, the manipulator grabs and sends it to the OP40 brake disc turning and grinding machine for fine grinding of the disc surface, and the mechanical processing process is completed;

7. After the surface grinding is completed, it is picked up by the manipulator and sent to the conveying roller table, and automatically enters the Dynamic Balancing Machine. If it is qualified, it will enter the next process, and if it is unqualified, it will enter the waste roller table;

8. After the dynamic balance detection is completed, it will be automatically sent to the typing machine for marking processing;

9. After the marking is completed, it is automatically sent to the unloading roller table, and then manually placed in the material basket. So far, all the processing and testing procedures have been completed.

Single machine introduction and configuration:

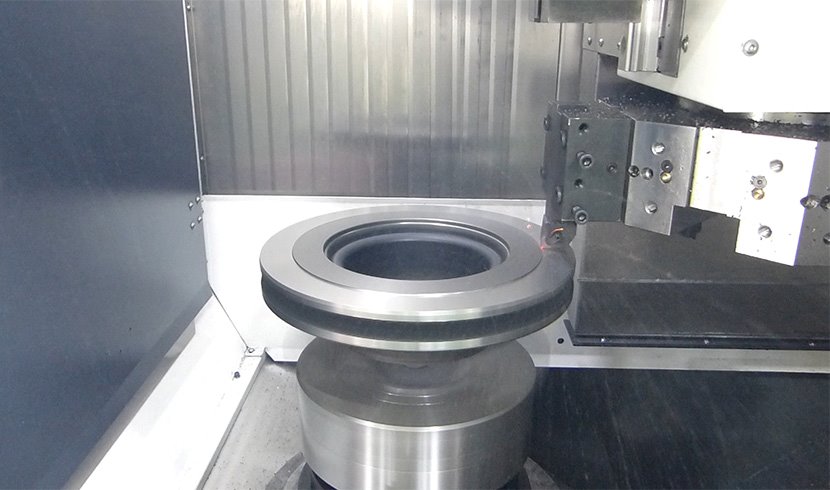

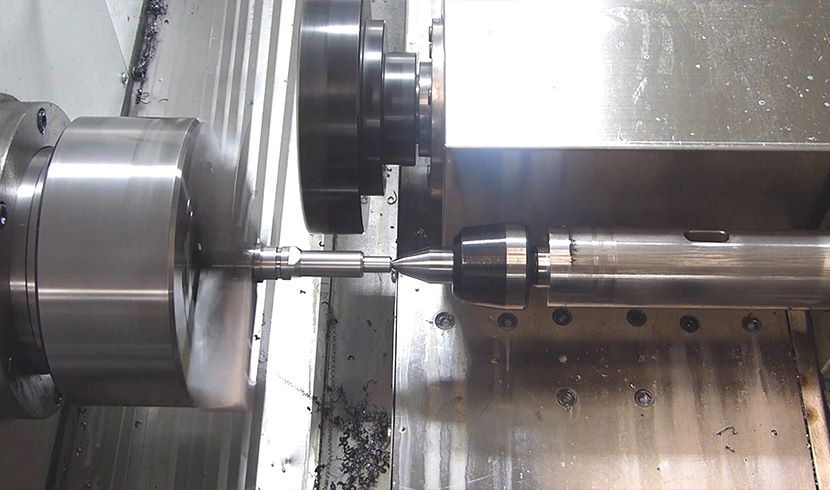

LYV-SD500 Double Station Brake Disc CNC Vertical Lathe (OP10, OP20) is a full CNC vertical lathe developed and produced by our company. It has high efficiency and high precision for the rough and fine machining of discs and drums. The equipment is equipped with an independent main shaft, which can achieve high speed, high torque and high precision; the feeding part adopts heavy-duty screw guide rails, and is equipped with highly closed multi-level protection, which makes the processing more stable and durable. Adopting double-turret processing technology, it can be processed independently or synchronously with two turrets, which truly realizes the rough and fine integrated follow-up processing technology. The tool holder can be equipped with double column single row tool and double column or double row tool structure, which is suitable for different products and different customer needs. The automatic door function can be used as a single machine, and it can also realize the automatic loading and unloading function of the manipulator of the multi-unit line.

CNC Drilling and Tapping Center OP30

This type of Drilling and Tapping Center has the advantages of high rigidity and high stability, which can quickly drill, twist and tap, and has the function of milling grooves. The speed of tool change is fast and accurate, and the stability of the equipment is excellent. It can be processed by a single machine or combined with an automatic line on-line. It is a model with a relatively high cost performance in the brake disc industry.

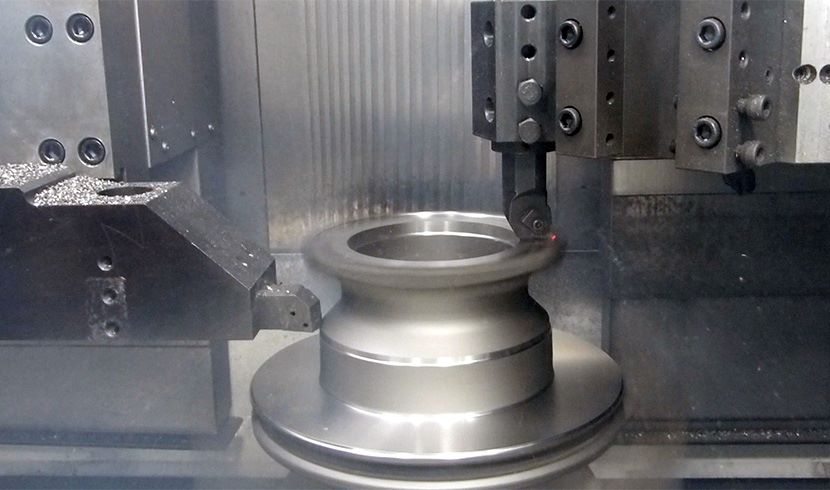

Brake Disc Turning and Grinding Machine OP40

LYV-L450 Brake Disc Turning and Grinding Machine is a machine tool specially developed and produced for the brake disc industry, integrating turning and grinding, mainly for processing brake discs after turning and processing and requesting grinding process, which can first carry out double-sided turning and processing of the disc surface, followed by grinding processing of the disc surface, completing multi-process processing with one-time clamping. The equipment is equipped with a special grinding machine spindle, which has the excellent performance of stable operation, high processing precision and high processing efficiency.

The design of this group of production lines is mainly aimed at the design and layout of mechanical processing and subsequent dynamic balancing and typing processes. It is designed according to different market needs and different needs of customers. It is recommended to assemble line equipment: 2 sets of LVY-SD500 Double Station Brake Disc CNC Vertical Lathe; 1 set of LYV-L450 Brake Disc Turning and Grinding Machine; 1 set of LV850 CNC Drilling and Tapping Center; 1 or 2 sets of manipulators.