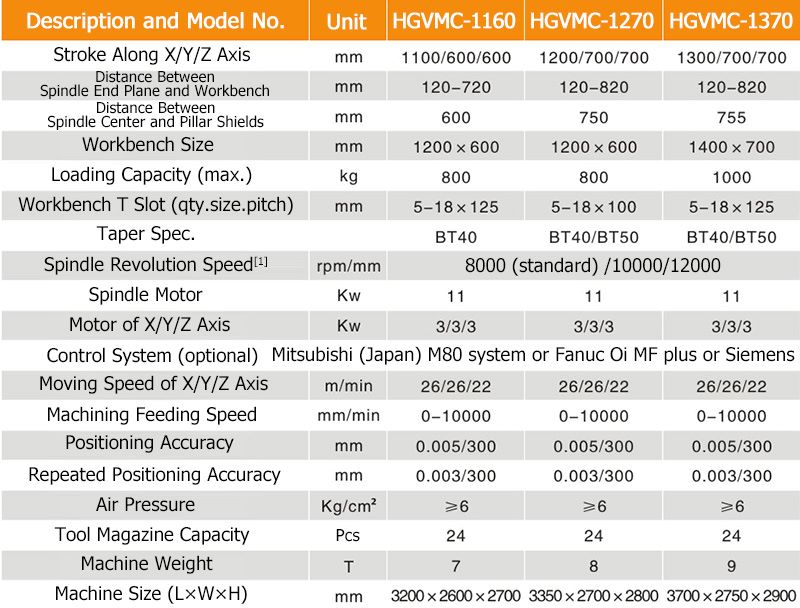

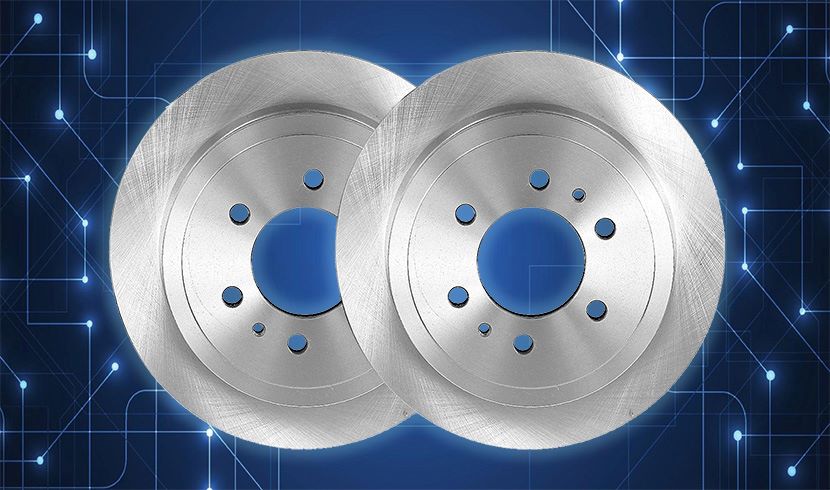

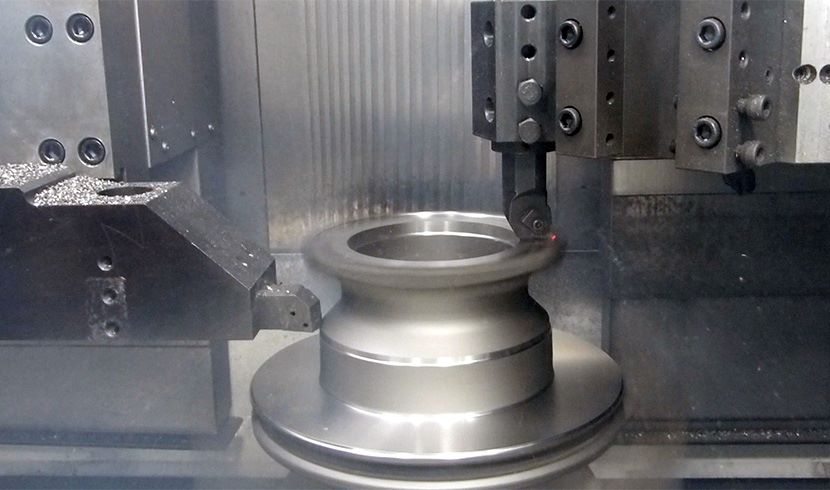

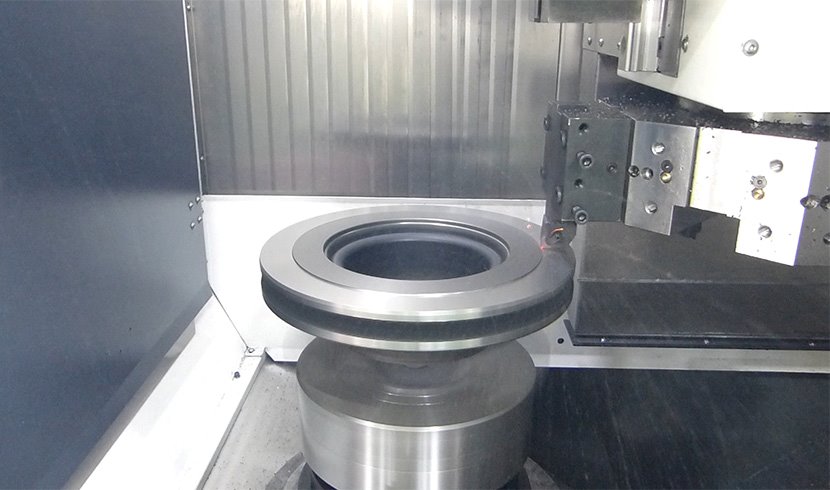

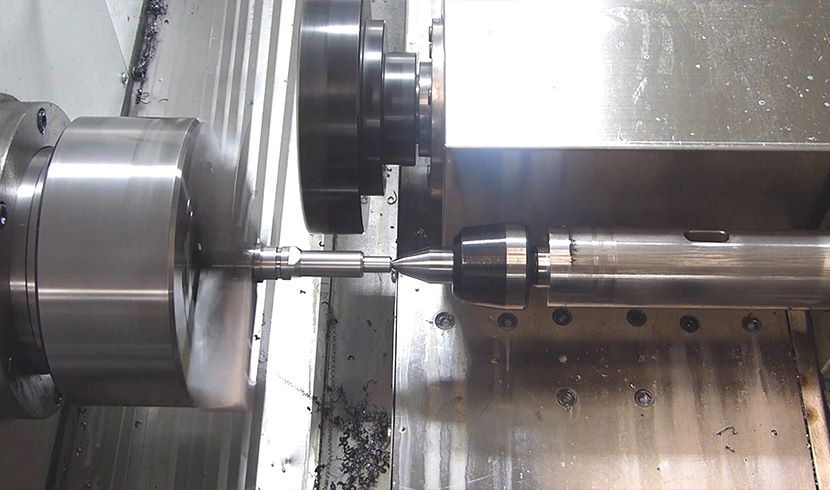

CNC Machining Center

HGVMC-1160 Two Line Machining Center

Material:

Delivery Date:

Description:

Model:

Online Consultation

Delivery Date:

Description:

Model: