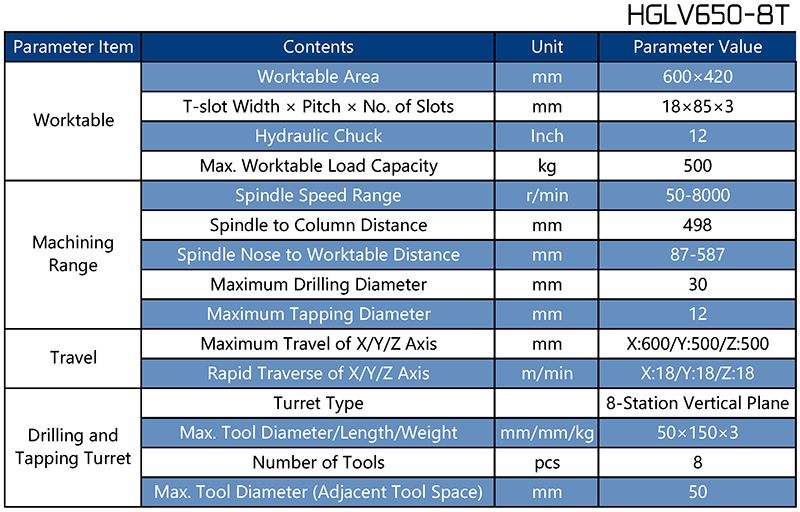

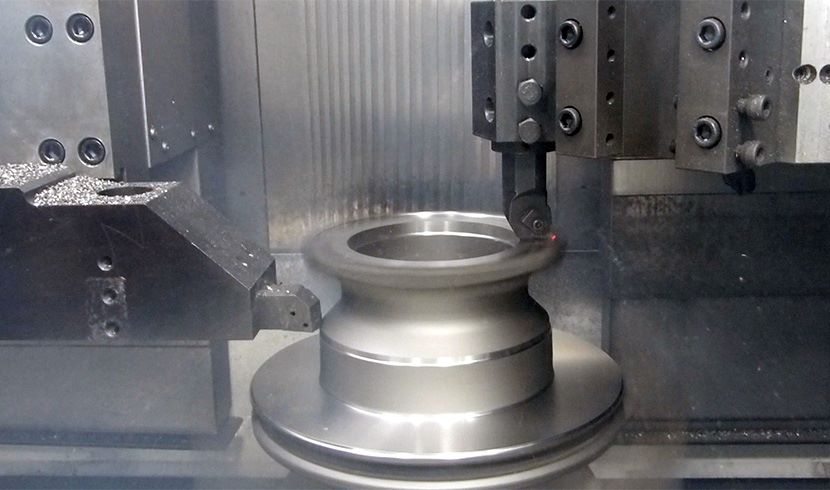

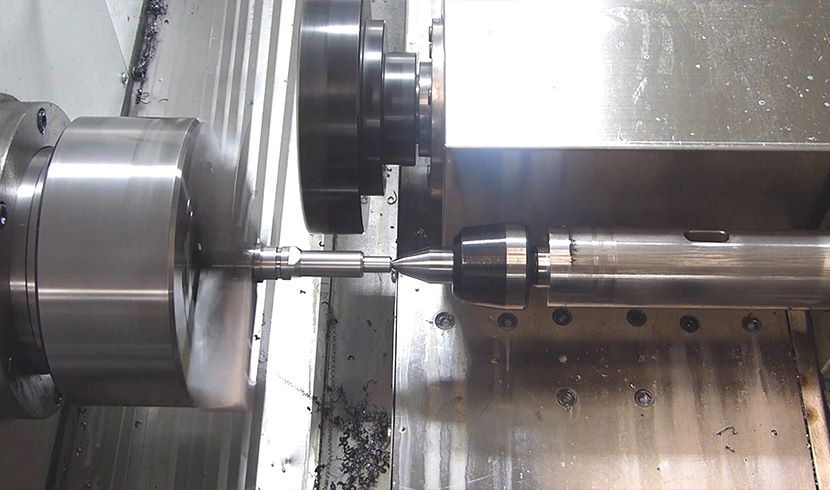

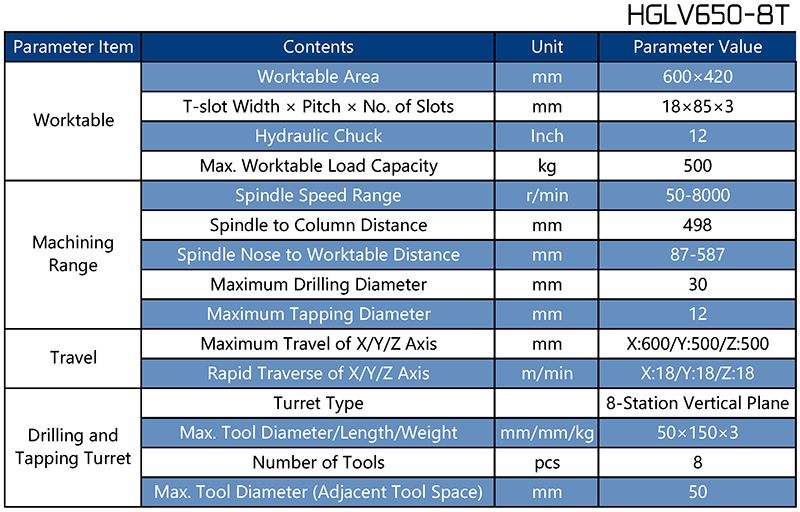

The HGLV650-8T Brake Disc Drilling & Tapping Machine is a three-axis controlled, full-featured high-speed precision CNC lathe, commonly referred to as a "Drilling, Milling & Tapping Center," "Drilling & Tapping Center," "Drilling & Milling Center," or "Drilling & Milling Machining Center." It is a market-leading machine that integrates cutting, drilling, and tapping functions, delivering both high efficiency and precision. The design prioritizes rigidity, accuracy, accuracy retention, ease of operation, and maintainability—key concerns for users.

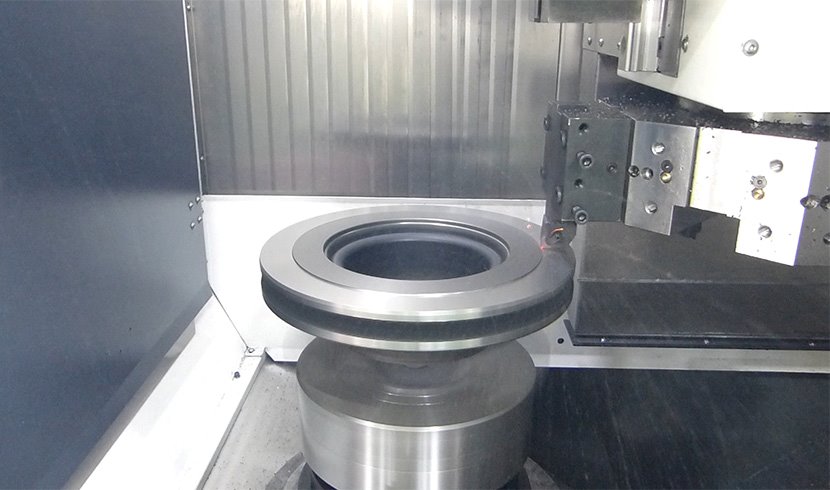

This machine is primarily used for automatic, high-efficiency, and precision drilling-tapping compound machining of automotive brake discs or other disc/sleeve components. It is also suitable for vertical turning and drilling-tapping compound machining of other parts, particularly in industries such as automotive, electric motors, and pumps for disc-type and shell-type components.

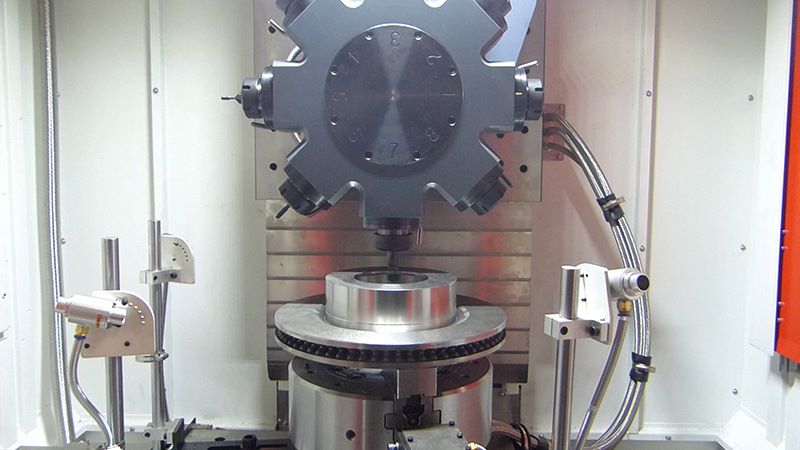

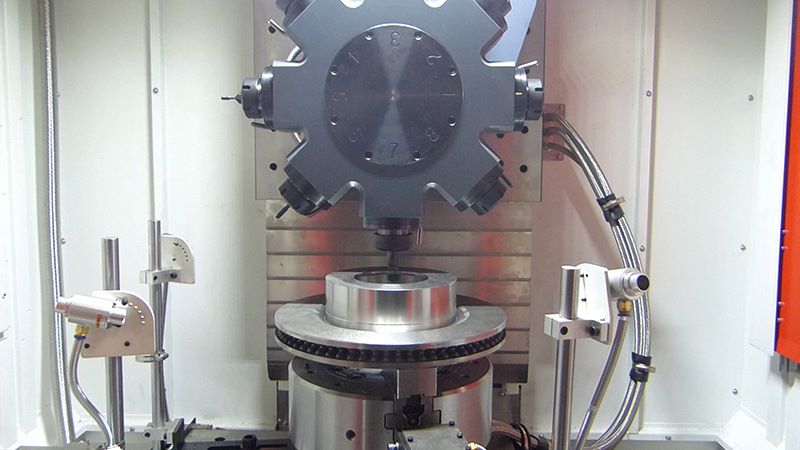

Equipped with an eight-station servo turret, the HGLV650-8T can accommodate 8 pre-adjusted tools that are pre-aligned before use. Automatic tool changing is enabled during processing, with each 45° rotation switching to the next tool, ensuring seamless tool changes according to the workpiece machining sequence.