Technical Support

The role and advantages of brake disc specialized machine

The brake disc specialized machine is a type of machine tool used specifically for processing automobile brake discs, which can achieve efficient, precise, and automated production of brake discs. Improving the accuracy and quality of brake discs also improves the braking performance and safety of automobiles. So, what is an automobile brake disc? And what is its function?

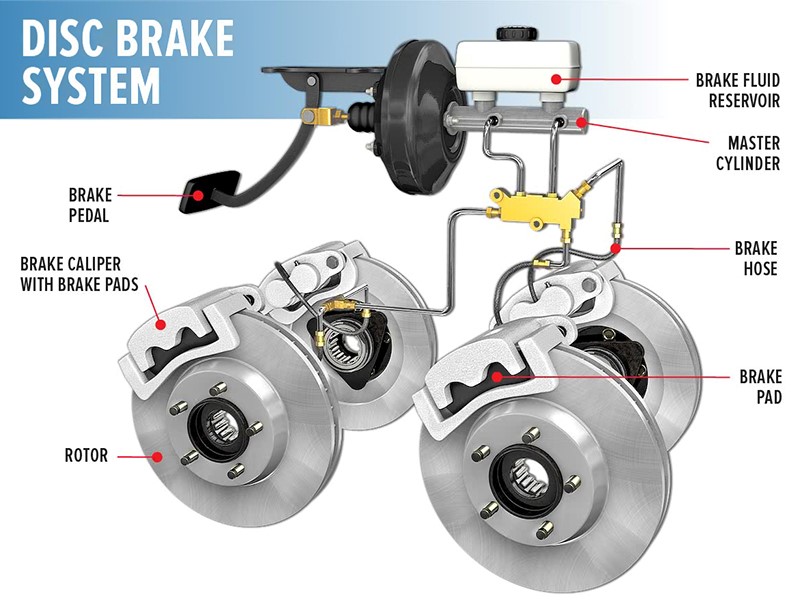

Disc Brake System

The automobile brake disc is an important component of the automobile braking system, which is used in conjunction with brake calipers and brake pads to convert the kinetic energy of the car into heat energy through frictional force, thereby reducing the speed or stopping the car. Automobile brake discs are usually made of materials such as cast iron or carbon ceramics, shaped like a circular flat disc, and installed on the hub.

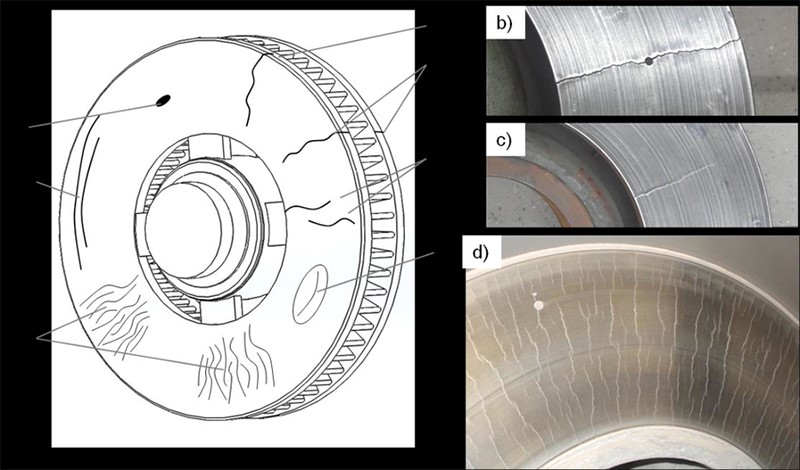

The quality of the automobile brake disc directly affects the driving safety and comfort of the car. If there are defects on the surface of the brake disc, such as unevenness, roughness, cracks, or deformation, it will cause problems such as poor braking effect, increased noise, and intensified vibration, and may even cause serious traffic accidents. Therefore, it is very necessary and important for automobile manufacturers and repairers to choose a high-quality CNC machine tool to process and inspect brake discs.

Defective Brake Discs

There are various types and specifications of brake disc specialized machines. According to different functions and structural characteristics, they can be divided into single spindle brake disc specialized machines, double spindle brake disc specialized machines, and dual tool position brake disc specialized machines. Among them, the double spindle brake disc specialized machine adopts the combination of positive and negative main spindles, equipped with automatic loading and unloading devices and mechanical hand transfer of workpieces, which can complete the processing of all inner and outer surfaces of the workpiece without turning over and automatically output the finished product. The dual tool position brake disc specialized machine uses two tool holders to process the workpiece simultaneously and has an adaptive function, which improves production efficiency while ensuring accuracy and surface quality.

Various Brake Disc Specialized Machines

Regardless of the type of brake disc specialized machine, the design and manufacturing process pays attention to the stability of the body structure, the precision of the main spindle structure, the durability of the guide rail screw, and the lubrication system. The advantages and functions of the brake disc specialized machine are not only reflected in the processing of the brake disc itself but also in the huge benefits it brings to the automobile manufacturing industry. Firstly, the brake disc specialized machine can improve the processing quality and consistency of brake discs, reduce scrap rates and repair rates, and reduce production costs and risks. Secondly, the brake disc specialized machine can improve the processing efficiency and production capacity of brake discs, shorten the delivery cycle, and meet market demand. Finally, the brake disc specialized machine can realize the intelligent, automated, and digital management of brake discs, facilitate the monitoring and adjustment of production parameters, and improve production flexibility and adaptability.

In summary, the brake disc specialized machine is a specialized, high-end, and intelligent machine tool equipment that provides a reliable, safe, and efficient solution for automobile braking systems, and also brings huge competitive advantages to the automobile manufacturing industry.

- Previous: Not available

- Next:Brake disc CNC lathe manufacturer tells you when to replace the brake disc.